As the first Basotect® customer, the room acoustics expert Bosig, Germany is now switching its product range to Basotect® EcoBalanced.

BASF’s thermoset is the world’s first high-quality melamine resin foam with a 50% lower Product Carbon Footprint (PCF) compared to Basotect® standard grades, helping to reduce the CO2 footprint of many sound absorption applications such as acoustic panels and sound absorbers in the construction industry. Thus, Basotect® EcoBalanced supports Bosig in reducing the use of fossil resources and the emission of greenhouse gases, taking another step towards climate neutrality.

“This year, Bosig is celebrating its 50th anniversary as an innovative problem solver for industry, trade and construction,” says Harry Leichmann, Managing Director of Bosig. “In this, BASF is one of our most reliable partners. We see Basotect® EcoBalanced as an important building block in our corporate strategy to continuously improve our energy and environmental performance. It fits perfectly into our forward-looking plans to provide our customers with sustainable and high- quality melamine resin foam products. The new acoustic solutions based on Basotect® EcoBalanced are available now, and we say thank-you to our distributors for joining us on this journey towards CO2 neutrality.”

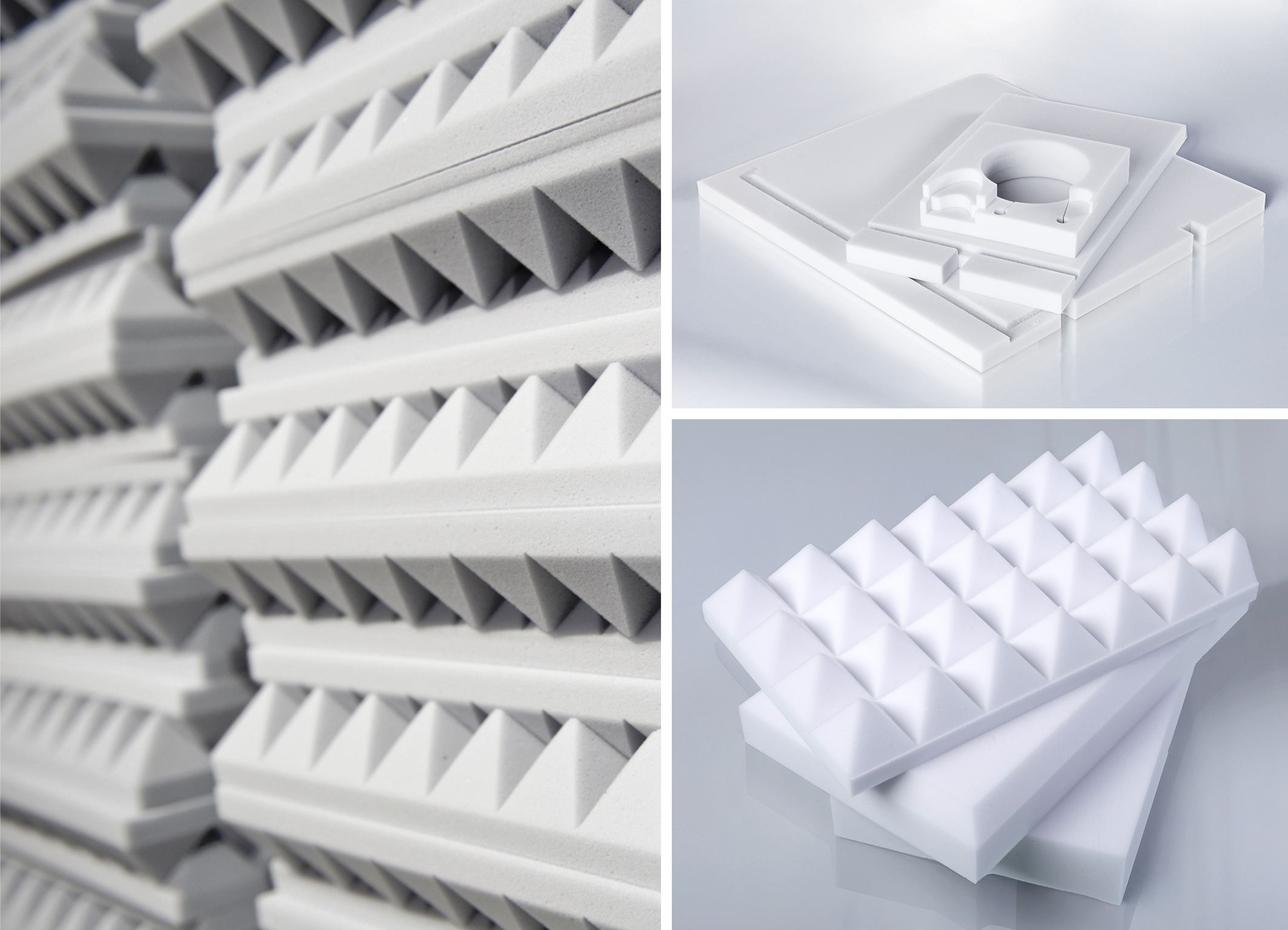

Bosig manufactures Basotect® into sound absorbers and acoustic panels of various shapes. It can refine and laminate the material as well as fit it up to become self-adhesive. Bosig’s oldest distribution partner Flexolan, Germany, will be the first retailer to switch its product range completely to Basotect® EcoBalanced.

“Not only Bosig is celebrating its anniversary this year, but also the partnership between Bosig and BASF,” says Tina Fries, responsible for Basotect® sales in Europe. “Our two companies have been working together in a spirit of trust for 20 years – so it came as no surprise to us that Bosig has recognized the benefits of Basotect® EcoBalanced and wants to use it to achieve its sustainability goals. With Basotect® EcoBalanced, Bosig can rely on the high material quality and reliable technical service that all our Basotect® customers are used to – and thus differentiate itself from the competition.”

BASF is the first company to have transparent emission data for its melamine resin foam. This helps customers to better measure and reduce the carbon footprint of their products in the construction industry – an industry that plays a crucial role in reducing global emissions.

Basotect® EcoBalanced: melamine resin foam with the lowest CO2 footprint on the market

Basotect® EcoBalanced is manufactured in a resource-efficient process using 100% green electricity; the fossil raw materials needed to produce it have been replaced with renewable feedstock at the very beginning of the production. The renewable feedstock comes from organic waste and residual biomass and is attributed to the Basotect® grade using a mass balance approach that is certified according to REDcert2 and ISCC PLUS.

Compared to other melamine resin foams on the market, e.g., Basotect® G+ EcoBalanced shows a PCF which is more than two- thirds lower (at a density of 9kg/m³). In comparison to alternative insulation materials like PET fleece (30kg/m³) it achieves considerably lower emissions. In addition to these sustainability advantages, Basotect® EcoBalanced is an easy drop-in solution: It shows the same material performance as respective standard grades. Processors of Basotect® EcoBalanced do not have to adapt existing manufacturing processes or invest additional money in new processing lines.